As more businesses and public spaces are available to reopen and return to regular operations, it is important to make sure the necessary precautions are taken. Remediation for COVID-19 requires more than just basic cleaning. Everywhere we go, we are witnessing cleaning and disinfecting like never seen before. At the grocery store shopping carts are being wiped down, doorknobs and gas pumps are being cleaned, nearly any surface we may encounter is being maintained for cleanliness constantly. This routine is what allows people to feel safe going out in public.

abrasive blasting

Luckily, the small surfaces are addressed quickly and with ease. However, the real problem is how do we scale the disinfecting/sanitizing routine to the levels that communities are going to require? What are the processes developed for large outdoor locations like bus stops, subway and train platforms and public gathering spaces? In many cases, the answer is nature’s best disinfectant: the UV rays from the sun, though even that is not all-inclusive. Business, local, and state governments will require a fast, reliable, and economical solution for remediation of COVID-19.

Cleaning Step 1: Wet Abrasive Blasting

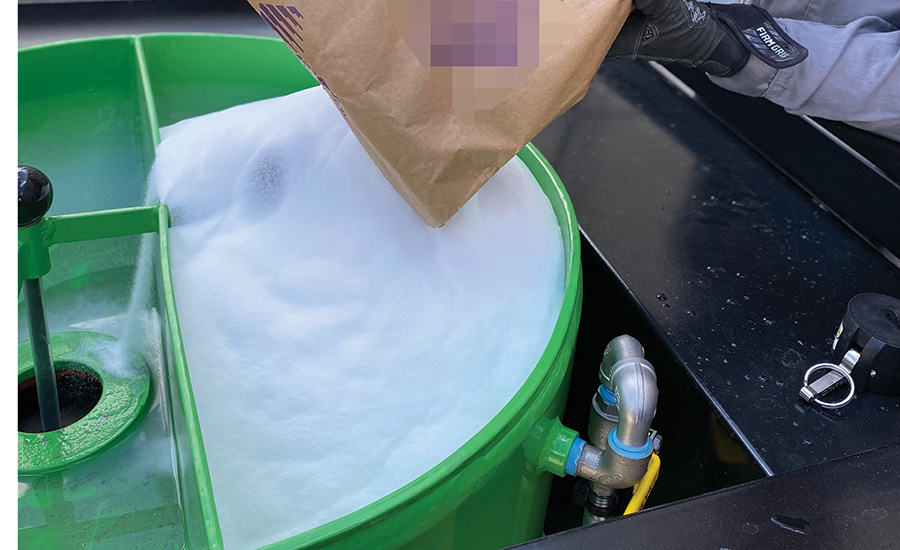

One of the most efficient and fastest ways to clean is abrasive blasting, particularly wet abrasive blasting. An example of wet abrasive blasting equipment (WAB) would be Greener Blast Technology GBT 760 slurry blast machine. Using wet abrasive blasting along with a nondestructive abrasive media, like sodium bicarbonate (baking soda), for a pre-clean, followed with a post application of a disinfectant and sanitizer can make the daunting task of cleaning and disinfecting fast and easy.

Cleaning exterior surfaces is critical in the disinfecting process as often over time bacteria can become encapsulated in contaminants, such as environmental materials, greases, oils, or grime which build up. Removal of these contaminants exposes the pest lurking beneath, allowing for optimal disinfecting. The first step in this process is cleaning with WAB unit.

When people think of abrasive blasting, they think of sand blasting which uses hard-abrasive media delivered with pressurized air and/or water to remove paint, rust, or for profiling a surface by the removal of substrate materials. The end-product of sand blasting is much different than soda blasting.

“The gentle physical propriety of baking soda yet aggressive cleaning ability is what makes it the only choice when surface preservation is required during cleaning,” said Brian Waple, business manager for ARMEX™. “Baking soda media, when used properly, will clean and remove contaminants all while not damaging what you are trying to remediate.”

Baking soda has been used as a nondestructive blast media for more than 30 years and has proven to be an outstanding option when non-destructive cleaning is required. When using baking soda with a WAB system, the operator is also able to utilize this material efficiently and with minimal to no visible transmissions of dust. In addition, soda blasting with a WAB unit is used at very low pressures of 30-40 PSI providing a safe work environment for the operator.

Cleaning Step 2: Disinfectant Application

The second step after the operator cleaned the desired surface is to apply an approved disinfectant and sanitizer. At this point, the operator uses the WAB unit’s built-in rinse feature to rinse the cleaned surface. It’s during this time that the rinse feature of these systems is very useful and will dispense the disinfectant solution from an onboard water tank.

When selecting a disinfectant, you must rely on the EPA-registered label as found on the product’s container.

Cole Stanton, Director of Education & AED Specification for ICP’s Building Solutions Group, says the “label is the law. Disinfectants kill pests and are therefore pesticides, as such, are regulated by the EPA.”

“Don’t lean heavily on what a rep states, or what appears on websites, or on the safety and product data sheets to ensure the proper product is selected for the project. Seek products with the most comprehensive label that targets your industry/profession,” Stanton said.

In the case of SARS-CoV-2 (the virus that causes COVID-19), the Environmental Protection Agency has developed another resource, the List N. This is to aid the U.S. public with prequalified disinfectants to choose from because it will be months or years before manufacturers can test against this new strain of coronavirus. List N, which includes both ICP’s ShockWave® and Benefect brands, is an interim index of products that can be used practically, and the EPA expects to be effective against SARS-CoV-2”.

At this point, the operator is to go back and rinse down the surface, removing all residual sodium bicarbonate while simultaneously coating the surface with disinfectant solution to the instructed level of wetness. The combination of air and water in the system allows the operator to efficiently dispense the disinfectant over very large surfaces very quickly. When disinfecting or sanitizing, it is especially important that all parts of the desired surface be sufficiently wet, allowing for the proper amount of dwell time for disinfection or sanitation, as required by the manufacturer’s disinfectant label. When the surface is deemed fully cleaned the operator has completed this process and is able to proceed to the next project.

The biggest message in all this? Be sure to read to all manufacturer’s EPA-registered label, as well as the Product Technical Sheets for use and application instructions. Also, always refer to manufactures SDS for proper PPE requirements and handling instructions.